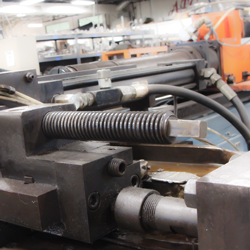

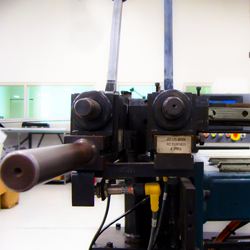

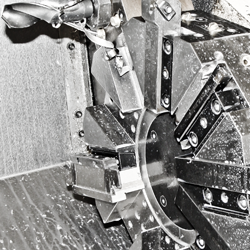

ATC Inc., is an Industry Leader in Precision Tooling and Production

Quality control is strictly enforced to meet our customer’s needs, as well as the ISO 9002, AS 9100 & BS EN 9002 requirements. Our products are inspected during every stage of production. Hydrostatic pressure testing is available up to 20, 000 PSI.

Materials Formed at ATC, INC., Include:

- Aluminum

- Stainless

- Titanium

- Copper

- Inconel

- Hastelloy

- Carbon

- Brass

ATC, Inc., retains close relationship with its subcontractors to provide the highest quality for:

- Painting

- Chem Film

- Anodize

- Dip Brazing

- Oxygen Cleaning

- Welding

- Heat Treating

- Radiographic Inspections

- Heat Resistant Insulation

- Non Destructive Testing

- Vapor Blasting

- Laser Part Marking

- Military Packaging

- Shot Peening

ATC, Inc., is currently an approved source for the following companies: